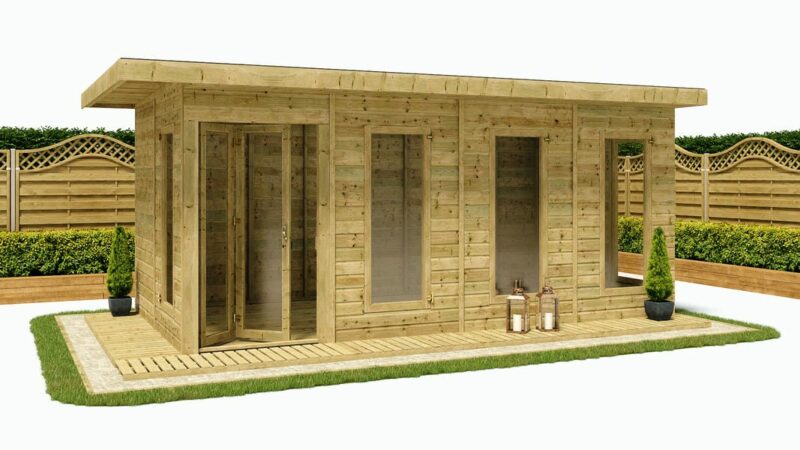

1. It’s all about the base

- A solid level base is required for your shed before you begin assembling it.

- Level paving slabs make a great choice if you are on a budget and have DIY skills to create it.

- A concrete base with sufficient drainage is an excellent choice for larger buildings as it provides a solid and long-lasting foundation for your building.

- A timber Eze Base is also an option if you have a building under 12ft wide. This provides a timber frame for your building which will need to be positioned level using levelling brackets for support posts.

2. Laying the floor sections

- Position your floor sections according to the instructions.

- The number of floor sections will depend on the size of your building.

- The floors can be screwed together with angled screws.

3. Fixing the starting wall panels

- The first two panels need to be fitted in the correct position for the rest of the panels to be assembled correctly.

- The back panel needs to be lined up to the join of the floor.

- The gable panel sits on the inside of the wall panel.

- The panels will overhang the floors slightly.

4. Fixing the wall panels

- The wall panels are screwed together with 50mm screws in the positions shown depending on your building size.

- The gable panel sections can be fitted together on the ground first then fixed in place.

5. Truss and roof support fixing

- The roof trusses are positioned at either 4ft or 3ft intervals depending on the size of your roof sections.

- If you have an OSB roof you will also need to fit the additional roof supports between the 4ft distances.

- The centre purlins will fit between the trusses.

6. Adding the roof sheets or panels

- For OSB roof sheets the timber eaves purlin will need to be fitted before the roof sheets are positioned.

- The roof sheets or panels fit between the roof trusses

- The roof sheets or panels need to be pushed up tight to the centre to make the building rigid.

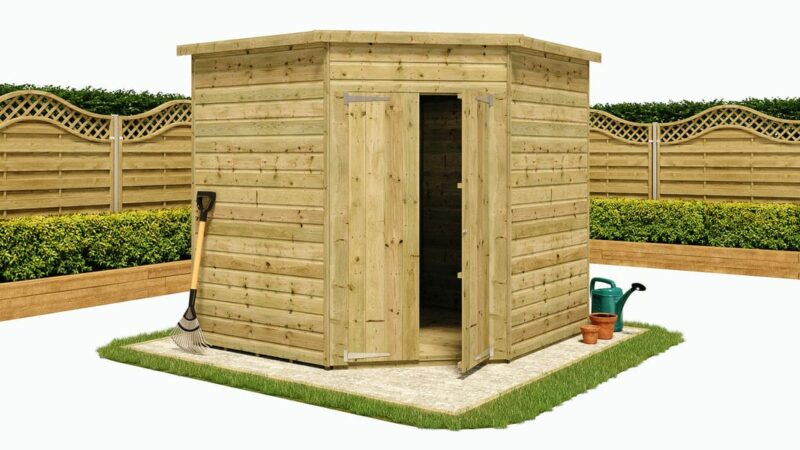

7. Fixing the doors and hinges

- The hinges are fitted to the doors with equal spacing.

- They are fitted to the doors before they are hung.

- Once the doors are fitted, tower bolts and turn buttons are fitted to hold the doors in place.

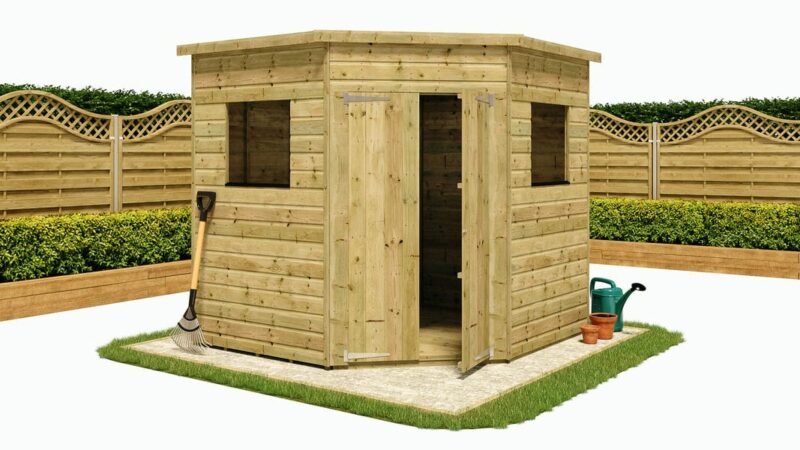

8. Glazing the windows

- The protective cover needs to be removed from the styrene before fitting

- The styrene glazing is fitted into the window opening and secured with beading strips.

- Cardboard can be used to protect the glazing from being scratched when the beading is fitted

9. Felting the shed

- The rolls of felt will need cutting to size with a sharp knife with some extra length to overhang the sides.

- The felt rolls are fitted on the sides of the roof first and then down the ridge.

- The felt is tacked in place with roof tacks at 100mm intervals

10. Adding the finishing touches

- The cloaking strips are added where the panels join.

- The fascias are added to the top of the gables and the finial in the centre.